WE’VE JOINED

FORCESiQ Power Tools products are now available

Learn More

exclusively through Bartell Global

CONCRETE

EQUIPMENTLevel up with professional

Learn More

placement and finishing tools,

for the perfect slab every time

Hardscaping

Learn More

Equipment

Explore Our Products

Saws

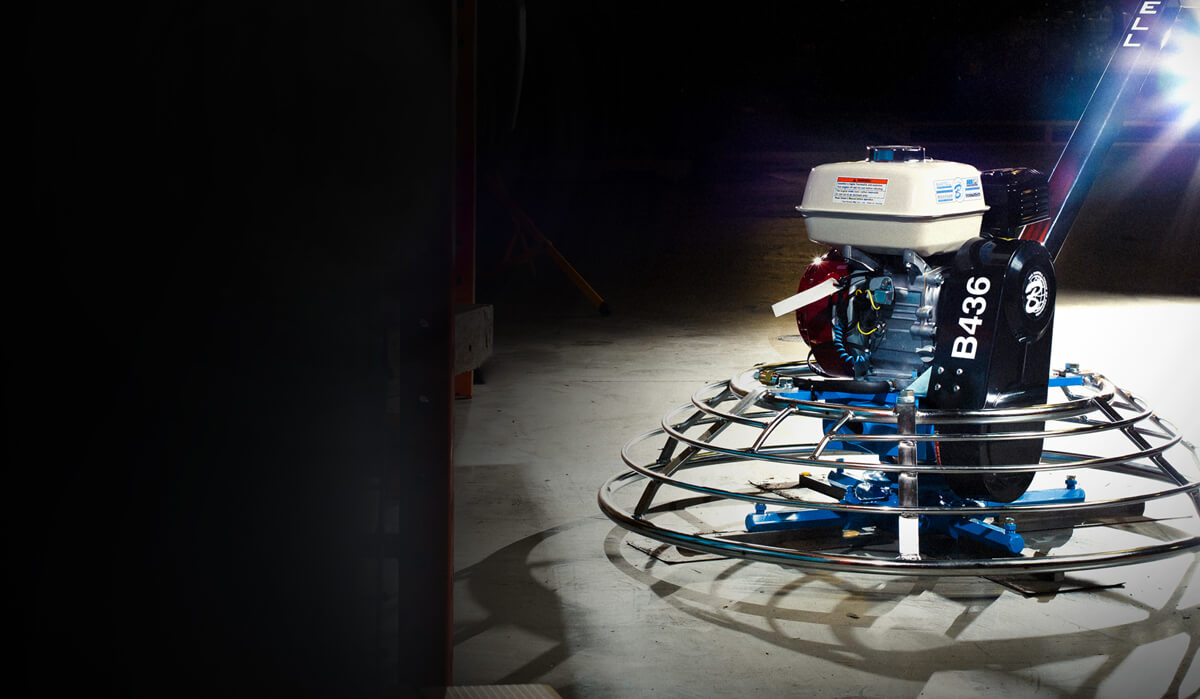

Walk Behind Trowels

Compaction

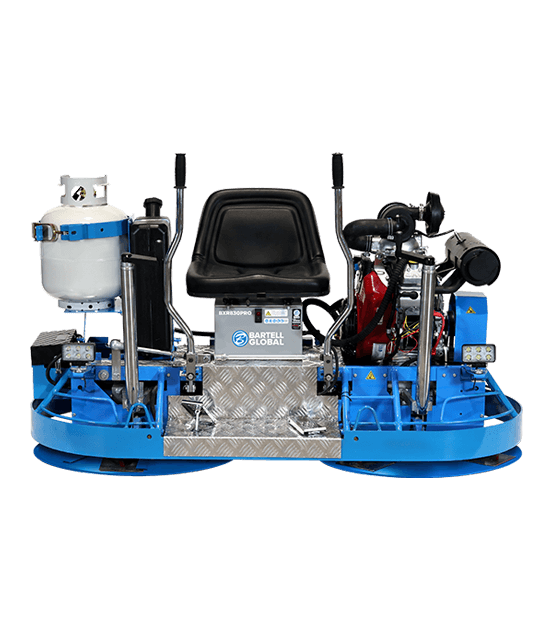

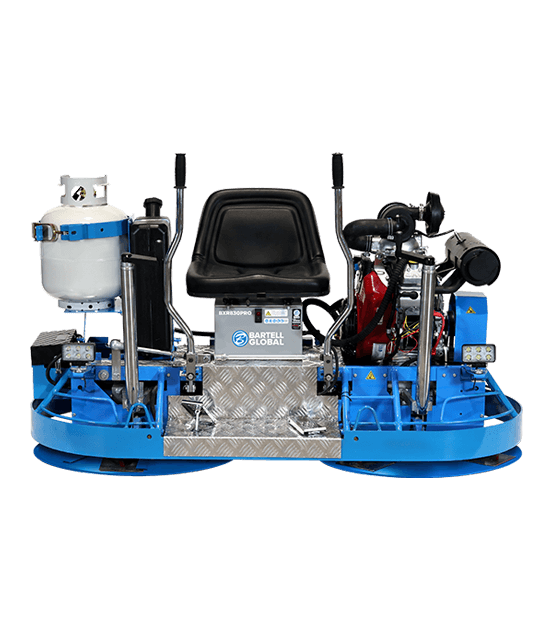

Ride-On Trowels

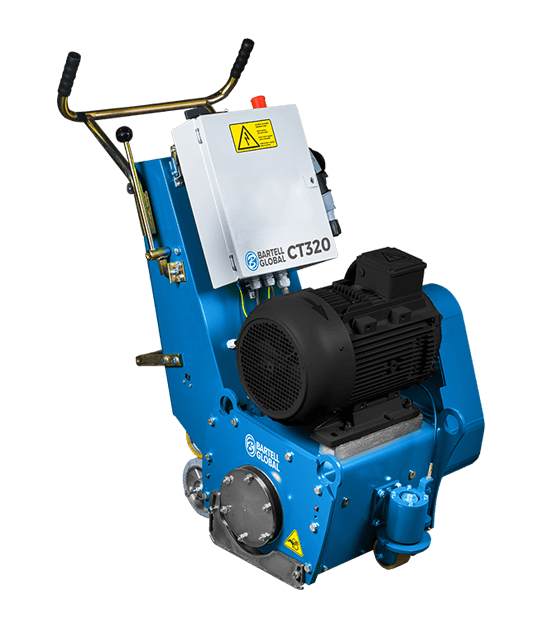

Floor Removal

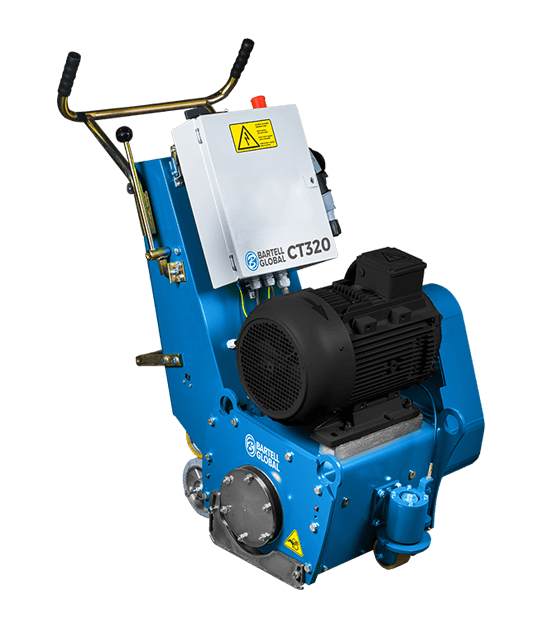

Scarifiers & Shavers

Generators

Power Buggies

Shotblasters

Dust Extractors

Grinders

Material Spreaders

Sprayers

Mixers

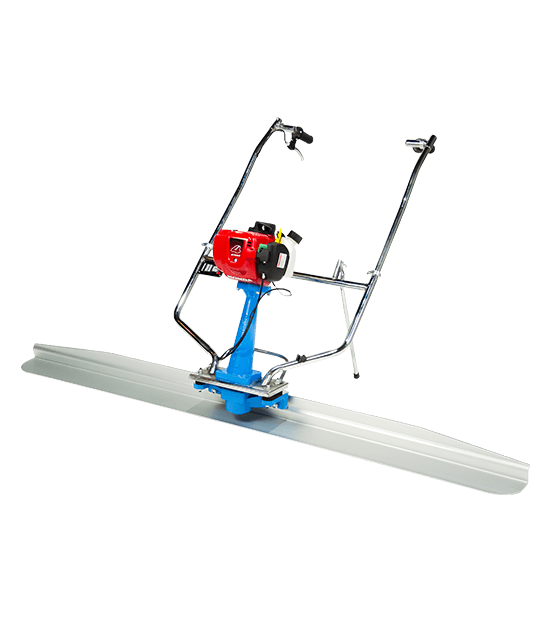

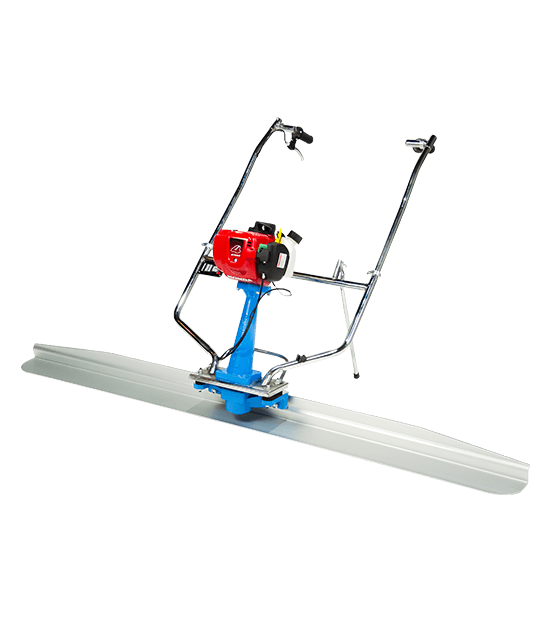

Screed

Floor Burnishers

Concrete Vibrators

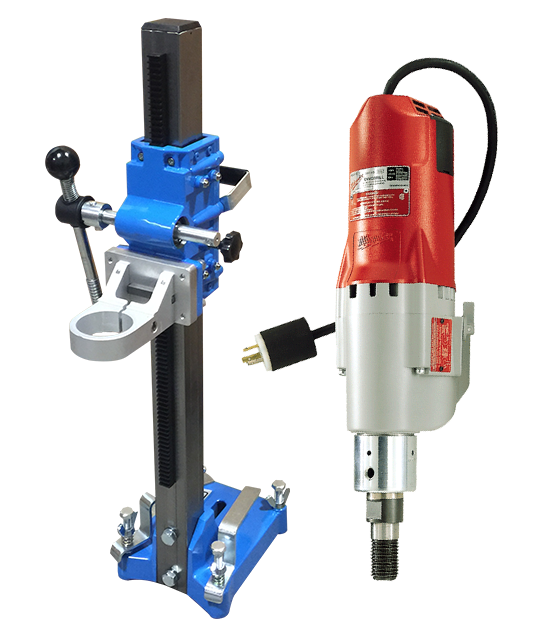

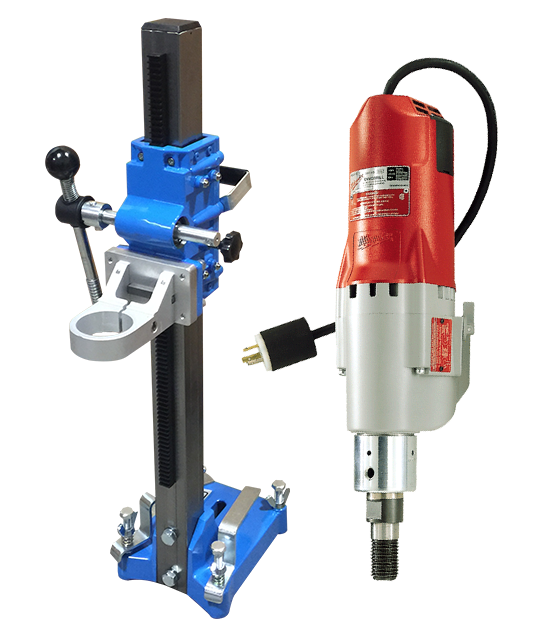

Core Drills & Stands

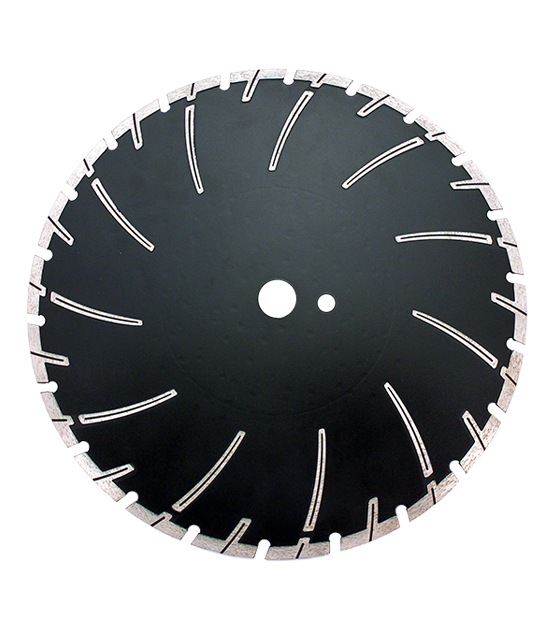

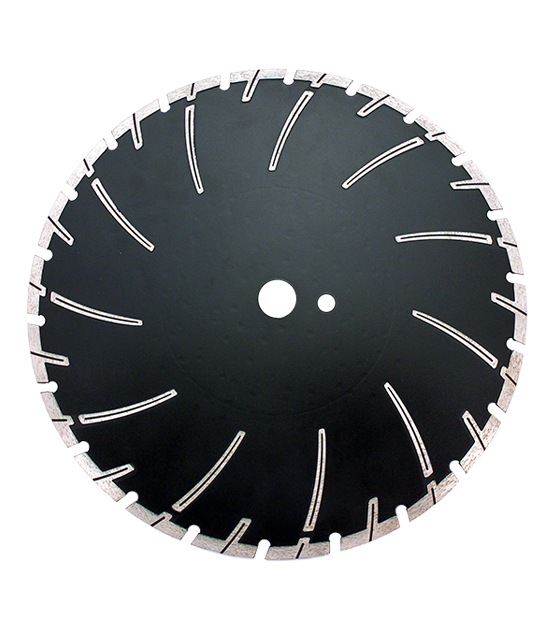

Diamond Blades

Diamond Tooling

Core Bits

Grinding Discs, Wheels, and Blocks

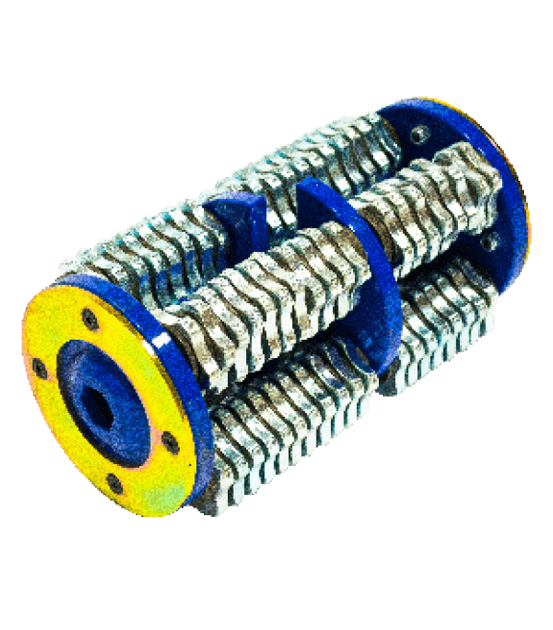

Floor Removal Tooling

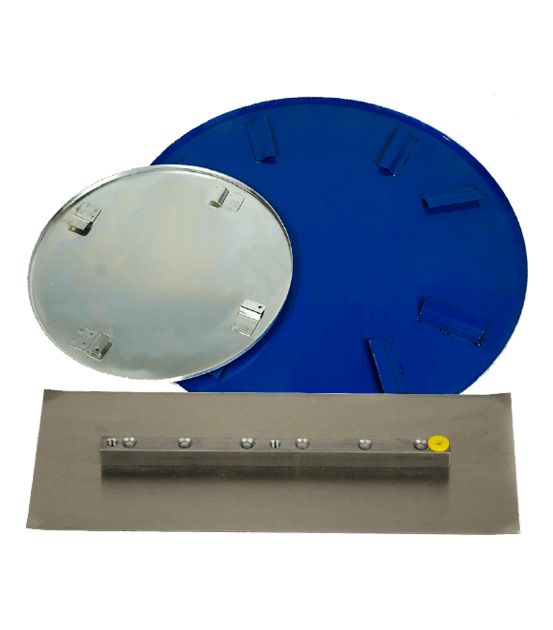

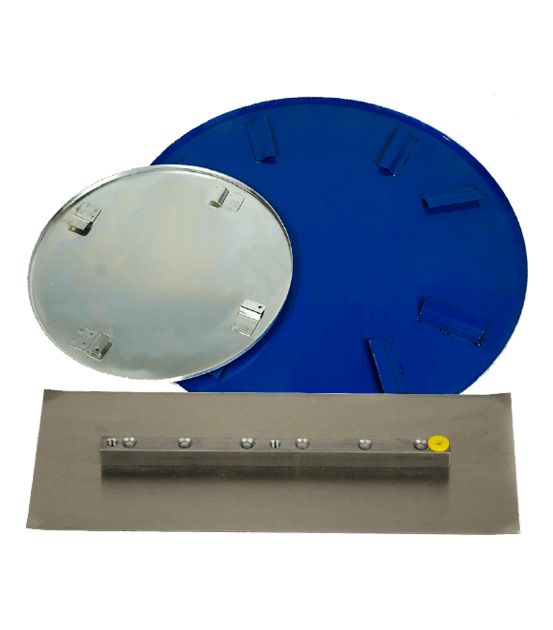

Trowel Blades & Float Pans

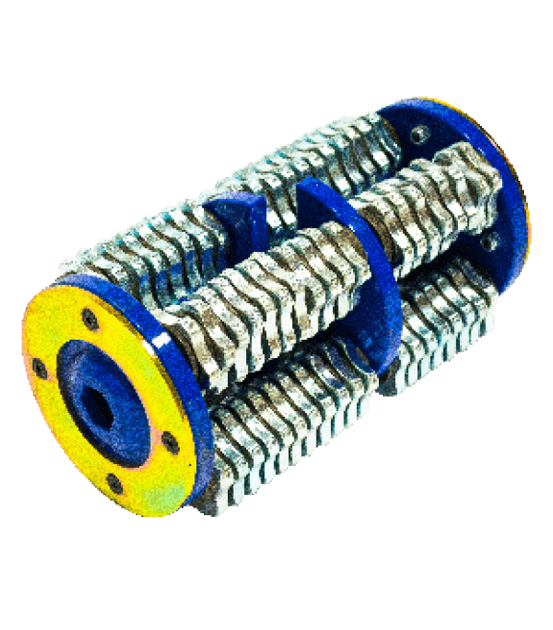

Scarifier Tooling

Saws

Walk Behind Trowels

Compaction

Ride-On Trowels

Floor Removal

Scarifiers & Shavers

Generators

Power Buggies

Shotblasters

Dust Extractors

Grinders

Material Spreaders

Sprayers

Mixers

Screed

Floor Burnishers

Concrete Vibrators

Core Drills & Stands

Diamond Blades

Diamond Tooling

Core Bits

Grinding Discs, Wheels, and Blocks

Floor Removal Tooling

Trowel Blades & Float Pans